How will you define a synchronous motor? These can be defined as electrical motors that are a kind of electro-mechanical devices which convert electrical into mechanical energies.

A synchronous motor is a three-phase motor. This is called so because when 3-phase electrical conductors are placed in a particular position, geometrically, implying at a certain angle from each other, this results in the production of an electrical field. This leads to rotation of the magnetic field at a specific speed which is called as synchronous speed. This is what you can call a synchronous motor.

What is a Permanent Magnet Synchronous Generator?

When the AC synchronous motor utilizes permanent magnets for producing field excitation, then this becomes a Permanent Magnet Synchronous Motor. These are known for high dynamic performance, are very efficient, fast, safe to use, are brushless, and has sinusoidal back EMF waveform, which is why such synchronous motors and generators are used across many applications in various industries and functions.

This includes permanent magnet rotor that generates high torque at zero speed, no rotor current and includes small frame size.

What is So Special About Permanent Magnet Motors?

Permanent magnet generators have mounted magnets instead of rotor winding mechanism that lead to generation of rotating magnetic field. Such motors are used with a digitally controlled inverter. There is no DC supply and thus these motors are low-cost and provide ease of simplicity in use.

Low rpm permanent magnet generators have the magnets equipped in the steel rotor that provides a consistent magnetic flux. These are also known to be similar to brushless DC motors in functioning.

When you want to find the best in this specific motor type, ensure that you consult with a reliable permanent magnet generator manufacturer in Delhi, or elsewhere, that can provide you with the best equipment deployment that aligns with your process requirement and delivers high-performance results for a longer time.

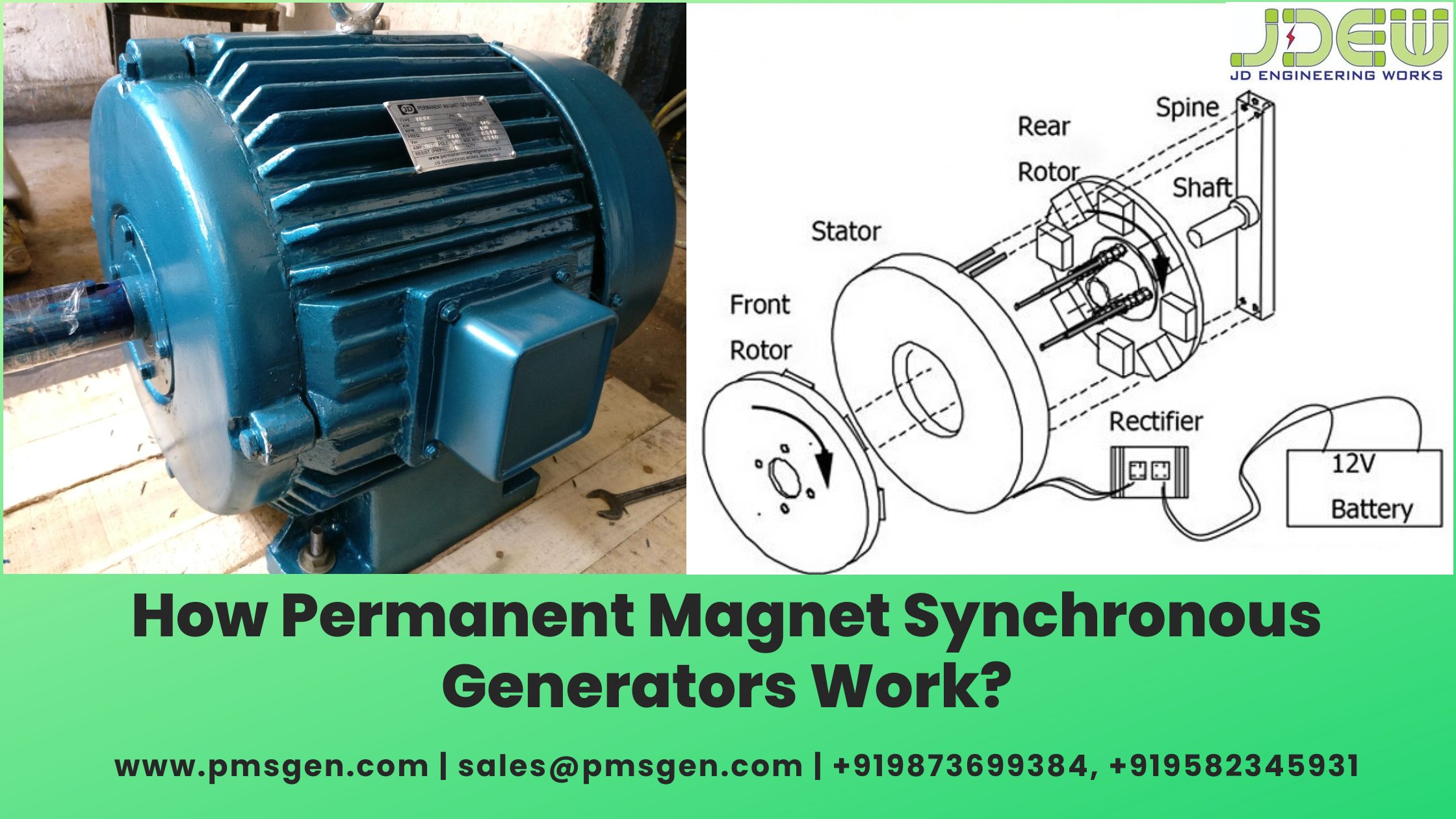

Construction of Permanent Magnet Generators

Like any other electric rotating motor, these also consist of a stator and a rotor. The construction principle of such motors is like a basic synchronous motor, but the rotor is what distinguishes it from them as the rotors have permanent magnets mounted on them, and also don’t include any field winding.

Permanent magnets used in such motors are made of boron, iron and samarium-cobalt that lend these with higher permeability. However, the most used permanent magnets you will find in permanent magnet synchronous generator is made up of neodymium-boron-iron because these are easy to find and are low-cost as well.

How Does a Permanent Magnet Generator Work?

The basic working principle of these generators is that these use permanent magnets, known as electromagnets (because of being subjected to electric current), to product electricity.

Permanent magnets are the most important equipment of these generators that power the entire working mechanism of these generators. Creating magnetic field, these ensure designing compact forms that ensures application in various purposes and functions.

What is the Characteristic of a Permanent Magnet Synchronous Generator?

- These work fast, clean and efficient

- Provides low audible noise

- Delivers high-speed performance, optimal torque, with no spark

- Safe to use in an explosive setting

- Effective to use on low-speed as well as high-speed operation

- Works with low rotor inertia

- Dissipate heat efficiently

Applications of Low RPM Permanent Magnet Generators

These generators are used across different industries and high-power applications that include machines, robotics, actuators, AC compressors, automotive electrical mechanisms, electrical equipment such as refrigerators and air conditions, servo drives, machine tools, traction control, data storage units, large power systems, aerospace industry and much more.

How Such Permanent Magnet Synchronous Generators are Controlled?

These are used and applied with a control system that could be a servo drive or a variable frequency. In fact, there are many implement control techniques and systems. The choice of which control method to utilize depends on the task that has to be performed. Fully-oriented control technique is used when the electric drive is required to deliver maximum performance.

What Benefits are Provided by Permanent Magnet Generators?

- Reliable Energy Output – These work irrespective of factors outside or inside of the premise, as these depend on the electromagnetic field creation, so no dependency on weather aspects.

- Free Energy–The electricity is generated by using permanent magnets which can also power other electric equipment, thereby no need to use costly electrical supply consumption.

- No Maintenance–These generators have a working mechanism and principle which requires no extensive effort of maintenance work concerning investment and money.

- Low Cost in Installation – The permanent magnet synchronous generator is easy to install that requires only a nominal cost as all. All you need are just basic elements and with low cost, little effort, and in quick time your installation gets done.

Conclusion: Your device will only work better when you know what specific generator you have to buy, for what purpose and how to get maximum performance from it. For this, it is important that you consult in detail with a permanent magnet generator manufacturer in Delhi, or wherever you stay.